- Benefits of Laser Cleaning for Glass Surfaces

- Comparison of Laser Cleaning vs. Traditional Cleaning Methods for Glass

- How Laser Cleaning Works on Glass Contaminants

- Case Studies of Successful Laser Cleaning on Glass Surfaces

- Safety Considerations for Laser Cleaning Glass

Benefits of Laser Cleaning for Glass Surfaces

Here are some of the key benefits of using laser cleaning for glass surfaces:

1. Non-contact cleaning: Laser cleaning is a non-contact process, which means that the laser beam does not physically touch the glass surface. This eliminates the risk of scratching or damaging the glass, making it a safe and gentle cleaning method.

2. Environmentally friendly: Laser cleaning does not require the use of harsh chemicals or abrasive materials, making it an environmentally friendly cleaning option. This can help reduce the amount of chemical waste produced and minimize the impact on the environment.

3. Efficient removal of contaminants: Laser cleaning is highly effective at removing a wide range of contaminants from glass surfaces, including dirt, grease, paint, and rust. The high-energy laser beam vaporizes the contaminants, leaving behind a clean and pristine surface.

4. Precision cleaning: Laser cleaning allows for precise control over the cleaning process, making it ideal for removing contaminants from intricate or delicate glass surfaces. The laser beam can be focused to target specific areas, ensuring thorough and consistent cleaning results.

5. Reduced downtime: Laser cleaning is a fast and efficient process that can significantly reduce cleaning time compared to traditional methods. This can help minimize downtime and increase productivity in industrial or commercial settings where glass surfaces need to be cleaned regularly.

6. Cost-effective: While the initial investment in laser cleaning equipment may be higher than traditional cleaning methods, the long-term cost savings can be significant. Laser cleaning is a low-maintenance and energy-efficient cleaning solution that can help reduce overall cleaning costs over time.

7. Versatile application: Laser cleaning can be used on a wide range of glass surfaces, including flat glass, curved glass, and even glass with complex shapes or patterns. This versatility makes it a versatile cleaning solution for a variety of industries and applications.

In conclusion, laser cleaning offers a number of benefits for cleaning glass surfaces, including non-contact cleaning, environmental friendliness, efficient removal of contaminants, precision cleaning, reduced downtime, cost-effectiveness, and versatile application. By choosing laser cleaning for glass surfaces, you can achieve superior cleaning results while minimizing the risk of damage to the glass and reducing the impact on the environment.

Comparison of Laser Cleaning vs. Traditional Cleaning Methods for Glass

Glass is a versatile material that is used in a wide range of applications, from windows and mirrors to glassware and electronics. Keeping glass clean is essential for maintaining its appearance and functionality. There are several methods for cleaning glass, including traditional methods such as scrubbing with soap and water, as well as more advanced techniques like laser cleaning. In this article, we will compare the effectiveness and efficiency of laser cleaning versus traditional cleaning methods for glass.

Traditional Cleaning Methods

Traditional cleaning methods for glass typically involve using a combination of water, soap, and a cleaning cloth or sponge. This method is effective for removing dirt, dust, and grime from the surface of the glass. However, traditional cleaning methods can be time-consuming and labor-intensive, especially when cleaning large or hard-to-reach surfaces. Additionally, traditional cleaning methods may not be able to remove stubborn stains or deposits from the glass.

Some common traditional cleaning methods for glass include:

– Scrubbing with soap and water

– Using glass cleaner sprays

– Wiping with a microfiber cloth

– Using vinegar or ammonia-based solutions

While traditional cleaning methods can be effective for routine maintenance, they may not be suitable for more intensive cleaning tasks or for delicate glass surfaces.

Laser Cleaning

Laser cleaning is a cutting-edge technology that uses high-powered lasers to remove contaminants from the surface of glass without the need for chemicals or abrasive materials. Laser cleaning is a non-contact method that is gentle on the glass surface, making it ideal for cleaning delicate or sensitive glass surfaces.

The process of laser cleaning involves directing a laser beam at the surface of the glass, which causes the contaminants to vaporize and be removed from the surface. Laser cleaning is highly effective at removing dirt, dust, grease, and other contaminants from glass surfaces, leaving them clean and residue-free.

Some benefits of laser cleaning for glass include:

– Non-contact cleaning method

– Environmentally friendly

– No chemicals or abrasive materials required

– Gentle on delicate glass surfaces

– Highly effective at removing contaminants

Comparison

When comparing laser cleaning to traditional cleaning methods for glass, there are several factors to consider:

– Effectiveness: Laser cleaning is highly effective at removing contaminants from glass surfaces, including stubborn stains and deposits that may be difficult to remove with traditional cleaning methods.

– Efficiency: Laser cleaning is a fast and efficient method for cleaning glass, especially for large or hard-to-reach surfaces. Traditional cleaning methods may be more time-consuming and labor-intensive.

– Environmental impact: Laser cleaning is an environmentally friendly method that does not require the use of chemicals or abrasive materials. Traditional cleaning methods may involve the use of harsh chemicals that can be harmful to the environment.

– Cost: While laser cleaning may have a higher upfront cost compared to traditional cleaning methods, it can be more cost-effective in the long run due to its efficiency and effectiveness.

In conclusion, laser cleaning is a highly effective and efficient method for cleaning glass surfaces, offering several advantages over traditional cleaning methods. While traditional cleaning methods may be suitable for routine maintenance, laser cleaning is the preferred choice for more intensive cleaning tasks or delicate glass surfaces. Consider using laser cleaning for your glass cleaning needs to achieve superior results with minimal environmental impact.

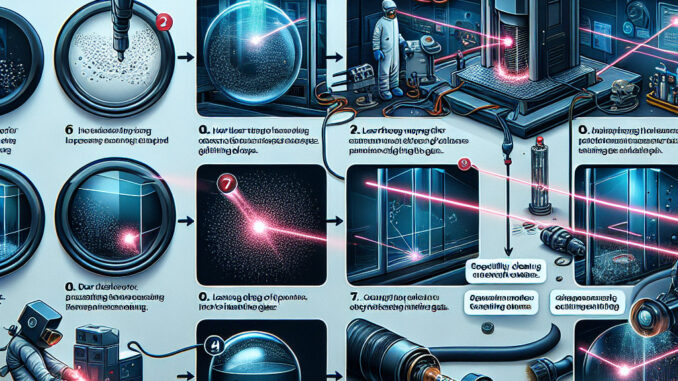

How Laser Cleaning Works on Glass Contaminants

Laser cleaning works by using a high-powered laser beam to vaporize or ablate contaminants from the surface of the glass. The laser beam is focused on the contaminated area, where it heats up and vaporizes the contaminants, leaving behind a clean and pristine glass surface. The process is highly precise and selective, allowing for targeted cleaning of specific areas without affecting the surrounding material.

One of the key advantages of laser cleaning is its ability to remove a wide range of contaminants from glass surfaces, including organic and inorganic substances, without the need for harsh chemicals or abrasive scrubbing. This makes it an environmentally friendly and sustainable cleaning solution that is safe for both the operator and the environment.

To better understand , let’s take a closer look at the process:

1. Laser System: A laser cleaning system consists of a high-powered laser source, optics for focusing the laser beam, and a control unit for adjusting the laser parameters. The laser beam is typically generated by a solid-state laser, such as a fiber laser or a diode-pumped laser, which emits a high-energy beam of light in the infrared or ultraviolet spectrum.

2. Contaminated Glass Surface: The glass surface to be cleaned is placed in the path of the laser beam, where it is exposed to the intense energy of the laser. The contaminants on the surface absorb the laser energy and are rapidly heated up, causing them to vaporize or ablate from the surface.

3. Contaminant Removal: As the contaminants are vaporized or ablated by the laser beam, they are carried away from the surface by a stream of gas or air. The clean glass surface is left behind, free of any residue or damage.

4. Control and Monitoring: The laser cleaning process can be controlled and monitored in real-time using feedback sensors and software algorithms. This allows for precise control of the laser parameters, such as power, pulse duration, and scanning speed, to optimize the cleaning efficiency and ensure uniform results.

5. Safety Precautions: Laser cleaning should be performed by trained operators wearing appropriate safety gear, such as laser safety glasses and protective clothing. The work area should be properly ventilated to remove any fumes or particles generated during the cleaning process.

In conclusion, laser cleaning is a highly effective and efficient method for removing contaminants from glass surfaces without causing any damage. Its non-contact nature, precision, and versatility make it an ideal solution for a wide range of applications, from industrial cleaning to restoration and conservation of historical artifacts. By harnessing the power of laser technology, we can achieve cleaner, safer, and more sustainable glass surfaces for a variety of uses.

Case Studies of Successful Laser Cleaning on Glass Surfaces

Case Study 1: Removing Paint from Glass Windows

One of the most common applications of laser cleaning on glass surfaces is the removal of paint. In this case study, a historic building with painted glass windows needed restoration. Traditional methods of paint removal were deemed too risky, as they could damage the delicate glass surface.

By using a laser cleaning system specifically designed for glass surfaces, the paint was successfully removed without any damage to the underlying glass. The laser was able to target the paint particles and vaporize them, leaving behind a clean and restored glass surface.

Case Study 2: Cleaning Solar Panels

Solar panels are another application where laser cleaning has proven to be effective on glass surfaces. In this case study, a solar farm in a dusty environment was experiencing reduced efficiency due to dirt and debris accumulating on the glass panels.

By using a laser cleaning system with adjustable power settings, the dirt and debris were effectively removed from the glass surface without causing any damage to the solar panels. The increased efficiency of the panels after cleaning resulted in a significant increase in energy production for the solar farm.

Case Study 3: Restoring Antique Glassware

Antique glassware often requires delicate cleaning methods to preserve its value and beauty. In this case study, a collection of antique glassware was covered in years of grime and dirt, making it difficult to appreciate the intricate designs and patterns.

Using a laser cleaning system with precise control over the cleaning parameters, the grime and dirt were gently removed from the glass surfaces, revealing the vibrant colors and intricate details of the antique glassware. The restored glassware was able to be displayed and appreciated once again.

Conclusion

These case studies demonstrate the versatility and effectiveness of laser cleaning on glass surfaces. Whether it’s removing paint from windows, cleaning solar panels, or restoring antique glassware, laser cleaning offers a safe and efficient solution for maintaining the beauty and functionality of glass surfaces.

Safety Considerations for Laser Cleaning Glass

Eye Protection

One of the most important safety considerations when using lasers for cleaning glass is eye protection. Laser beams can cause serious damage to the eyes if proper precautions are not taken. It is essential to wear appropriate laser safety goggles that are designed to block the specific wavelength of the laser being used.

Skin Protection

In addition to eye protection, it is also important to protect the skin from exposure to laser beams. Laser beams can cause burns and other skin damage if they come into direct contact with the skin. It is recommended to wear long sleeves and gloves when operating a laser cleaning system.

Ventilation

Another important safety consideration for laser cleaning glass is ventilation. Laser cleaning can produce fumes and particles that may be harmful if inhaled. It is important to ensure that the work area is well-ventilated to prevent the buildup of harmful fumes and particles.

Training

Proper training is essential for anyone using a laser cleaning system. It is important to understand how to operate the system safely and effectively. Training should cover proper safety procedures, including how to use protective equipment and how to handle the laser cleaning system properly.

Emergency Procedures

In the event of an accident or injury while using a laser cleaning system, it is important to have emergency procedures in place. This may include knowing how to shut off the laser quickly and safely, as well as knowing how to respond to injuries such as burns or eye damage.

Conclusion

Overall, laser cleaning is a highly effective method for cleaning glass surfaces, but it is important to take proper safety precautions when using lasers for this purpose. By following the safety considerations outlined in this article, you can ensure that laser cleaning glass is done safely and effectively.

| Safety Consideration | Description |

|---|---|

| Eye Protection | Wear appropriate laser safety goggles |

| Skin Protection | Wear long sleeves and gloves |

| Ventilation | Ensure work area is well-ventilated |

| Training | Proper training on how to operate the system safely |

| Emergency Procedures | Have emergency procedures in place |

- Laser cleaning for removing contaminants from glass surfaces - 2 August 2024

- 5 challenges in digitization in medical branch and pharmaceutical branch - 22 April 2024

- What is a tech stack and why does it matter? - 28 January 2024