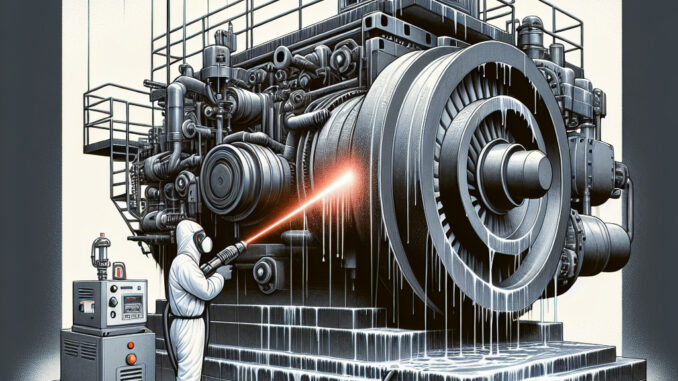

- Introduction to laser cleaning technology

- History and development of laser cleaning for machinery

- Challenges and limitations of laser cleaning technology

- Laser cleaning for removing oil and grease from automotive machinery

- Laser cleaning for removing oil and grease from food processing machinery

- Laser cleaning for removing oil and grease from power generation machinery

- Laser cleaning for removing oil and grease from chemical processing machinery

- Laser cleaning for removing oil and grease from packaging machinery

Introduction to laser cleaning technology

Technologia czyszczenia laserowego jest innowacyjnym rozwiązaniem, które znacząco przyczynia się do poprawy efektywności procesów czyszczenia w różnych dziedzinach. Wykorzystuje ona moc lasera do usuwania zanieczyszczeń, warstw powierzchniowych i innych substancji niepożądanych z różnych materiałów. W porównaniu do tradycyjnych metod czyszczenia, takich jak ścieranie, szlifowanie czy użycie chemikaliów, technologia czyszczenia laserowego oferuje wiele korzyści, takich jak precyzja, szybkość i bezpieczeństwo.

Podstawowym elementem technologii czyszczenia laserowego jest laser, czyli urządzenie generujące wiązkę światła o wysokiej intensywności. Laser emituje promieniowanie elektromagnetyczne, które jest skoncentrowane w jednym punkcie, co umożliwia precyzyjne i skuteczne usuwanie zanieczyszczeń. Istnieje wiele rodzajów laserów, które mogą być stosowane w technologii czyszczenia, takich jak lasery CO2, lasery Nd:YAG, lasery diodowe czy lasery impulsowe.

Proces czyszczenia laserowego polega na skierowaniu wiązki lasera na powierzchnię, która ma zostać oczyszczona. Energia lasera powoduje odparowanie lub odłuszczenie zanieczyszczeń, co prowadzi do ich usunięcia. Technologia ta jest nieinwazyjna, ponieważ nie wymaga bezpośredniego kontaktu z powierzchnią, co minimalizuje ryzyko uszkodzenia materiału. Ponadto, laser może być precyzyjnie kontrolowany, co umożliwia czyszczenie trudno dostępnych miejsc i skomplikowanych kształtów.

Zastosowanie technologii czyszczenia laserowego jest szerokie i obejmuje wiele branż. W przemyśle motoryzacyjnym, laser jest wykorzystywany do czyszczenia silników, felg, elementów karoserii i innych części pojazdów. W przemyśle lotniczym, technologia ta jest stosowana do czyszczenia skrzydeł samolotów, silników, kabin i innych powierzchni. W przemyśle spożywczym, laser jest używany do czyszczenia maszyn i urządzeń, które są narażone na kontakt z żywnością. Ponadto, technologia czyszczenia laserowego znajduje zastosowanie w dziedzinach takich jak konserwacja zabytków, medycyna, elektronika, przemysł drzewny i wiele innych.

Korzyści wynikające z zastosowania technologii czyszczenia laserowego są liczne. Po pierwsze, jest to metoda nieinwazyjna, która minimalizuje ryzyko uszkodzenia materiału. Po drugie, laser jest precyzyjnie kontrolowany, co umożliwia czyszczenie trudno dostępnych miejsc i skomplikowanych kształtów. Po trzecie, technologia ta jest szybka i efektywna, co przyczynia się do zwiększenia wydajności procesów czyszczenia. Po czwarte, laser nie wymaga użycia chemikaliów, co sprawia, że jest bardziej przyjazny dla środowiska. Po piąte, technologia czyszczenia laserowego jest bezpieczna dla operatorów, ponieważ minimalizuje ryzyko wystąpienia urazów związanych z tradycyjnymi metodami czyszczenia.

Wnioski

Technologia czyszczenia laserowego jest innowacyjnym rozwiązaniem, które znacząco poprawia efektywność procesów czyszczenia w różnych dziedzinach. Wykorzystanie lasera do usuwania zanieczyszczeń i innych substancji niepożądanych oferuje wiele korzyści, takich jak precyzja, szybkość i bezpieczeństwo. Zastosowanie tej technologii jest szerokie i obejmuje wiele branż, od przemysłu motoryzacyjnego i lotniczego po przemysł spożywczy i konserwację zabytków. Korzyści wynikające z zastosowania technologii czyszczenia laserowego są liczne, w tym minimalizacja ryzyka uszkodzenia materiału, precyzyjne czyszczenie trudno dostępnych miejsc, szybkość i efektywność, przyjazność dla środowiska oraz bezpieczeństwo dla operatorów.

Słowa kluczowe: technologia czyszczenia laserowego, laser, zanieczyszczenia, precyzja, szybkość, bezpieczeństwo, przemysł motoryzacyjny, przemysł lotniczy, przemysł spożywczy, konserwacja zabytków.

Frazy kluczowe: innowacyjne rozwiązanie technologiczne do czyszczenia, usuwanie zanieczyszczeń za pomocą lasera, precyzyjne czyszczenie trudno dostępnych miejsc, szybkie i efektywne usuwanie zanieczyszczeń, bezpieczne i przyjazne dla środowiska czyszczenie laserowe.

History and development of laser cleaning for machinery

The concept of using lasers for cleaning purposes can be traced back to the 1960s when the first laser was invented. However, it was not until the 1980s that researchers began to explore the potential of lasers in the field of cleaning. Initially, lasers were primarily used for cutting and welding applications, but their ability to remove contaminants from various surfaces soon caught the attention of scientists and engineers.

Advancements in Laser Technology:

As laser technology continued to evolve, researchers started experimenting with different laser types and wavelengths to optimize the cleaning process. Initially, CO2 lasers were commonly used due to their high power output. However, they were limited in terms of precision and control. With the advent of solid-state lasers, such as Nd:YAG and fiber lasers, laser cleaning became more efficient and versatile.

The Development of Laser Cleaning Systems:

In the early stages, laser cleaning was a manual process, where operators had to manually direct the laser beam onto the surface to be cleaned. This method was time-consuming and required skilled personnel. However, with advancements in automation and robotics, laser cleaning systems were developed, allowing for automated and precise cleaning of machinery. These systems incorporated scanning heads and motion control systems to ensure uniform cleaning and reduce human error.

Applications of Laser Cleaning in Machinery:

Laser cleaning has found numerous applications in the machinery industry. It is commonly used for removing rust, paint, grease, and other contaminants from various surfaces, including metal, plastic, and glass. Laser cleaning is particularly beneficial for delicate machinery parts that cannot withstand traditional cleaning methods involving chemicals or abrasive materials. It ensures thorough cleaning without causing any damage or alteration to the surface.

Benefits of Laser Cleaning:

Laser cleaning offers several advantages over traditional cleaning methods. Firstly, it is a non-contact process, eliminating the risk of surface damage or distortion. Secondly, it is a dry process, eliminating the need for water or chemicals, making it environmentally friendly. Additionally, laser cleaning is highly precise, allowing for selective removal of contaminants without affecting the underlying material. It also reduces the need for manual labor, saving time and costs.

Future Developments and Challenges:

The future of laser cleaning for machinery looks promising, with ongoing research and development focusing on improving efficiency, reducing costs, and expanding its applications. Researchers are exploring new laser types, such as ultrashort pulse lasers, which offer enhanced precision and control. However, challenges remain, including the high initial investment cost of laser cleaning systems and the need for skilled operators to ensure optimal results.

Keywords: laser cleaning, machinery, history, development, technology, automation, applications, benefits, future, challenges.

Long-tail phrases:

1. History of laser cleaning for machinery.

2. Advancements in laser cleaning technology.

3. Applications of laser cleaning in the machinery industry.

4. Benefits of laser cleaning for delicate machinery parts.

5. Future developments and challenges in laser cleaning for machinery.

Challenges and limitations of laser cleaning technology

Wyzwania technologii czyszczenia laserowego:

1. Ograniczenia materiałowe: Nie wszystkie materiały są odpowiednie do czyszczenia laserowego. Niektóre materiały, takie jak tworzywa sztuczne, mogą ulec uszkodzeniu lub topnieniu pod wpływem intensywnego promieniowania laserowego. Ponadto, niektóre powierzchnie, takie jak powierzchnie malowane, mogą być wrażliwe na działanie lasera i mogą ulec zniszczeniu.

2. Bezpieczeństwo: Technologia czyszczenia laserowego wymaga odpowiednich środków ostrożności, ponieważ promieniowanie laserowe może być szkodliwe dla ludzi i zwierząt. Konieczne jest stosowanie odpowiednich zabezpieczeń, takich jak specjalne okulary ochronne, aby uniknąć uszkodzeń oczu.

3. Koszty: Inwestycja w urządzenia do czyszczenia laserowego może być kosztowna. Laserowe systemy czyszczące są zazwyczaj droższe niż tradycyjne metody czyszczenia, co może stanowić wyzwanie dla małych przedsiębiorstw lub osób prywatnych.

4. Skomplikowane zanieczyszczenia: Niektóre zanieczyszczenia, takie jak rdza lub farba, mogą być trudne do usunięcia za pomocą technologii czyszczenia laserowego. W takich przypadkach konieczne może być zastosowanie innych metod czyszczenia lub kombinacja różnych technologii.

5. Efekty uboczne: Czyszczenie laserowe może powodować pewne efekty uboczne, takie jak zmiany w strukturze powierzchni lub utrata koloru. W niektórych przypadkach może być konieczne przeprowadzenie dodatkowych działań, takich jak polerowanie lub malowanie, aby przywrócić pierwotny wygląd powierzchni.

Ograniczenia technologii czyszczenia laserowego:

1. Rozmiar i kształt przedmiotów: Technologia czyszczenia laserowego może być ograniczona przez rozmiar i kształt czyszczonych przedmiotów. Niektóre urządzenia mogą mieć ograniczenia co do wielkości przedmiotów, które mogą być czyszczone, co może stanowić problem przy czyszczeniu dużych lub nieregularnych powierzchni.

2. Czas trwania procesu: Czyszczenie laserowe może być czasochłonne, szczególnie w przypadku dużych powierzchni lub trudnych do usunięcia zanieczyszczeń. Proces ten może wymagać wielokrotnego przeprowadzenia, aby osiągnąć pożądane rezultaty.

3. Zasięg lasera: Promieniowanie laserowe ma ograniczony zasięg, co oznacza, że niektóre trudno dostępne miejsca mogą być trudne do oczyszczenia za pomocą tej technologii. Konieczne może być zastosowanie innych metod czyszczenia lub użycie specjalnych narzędzi, aby dotrzeć do tych obszarów.

4. Wpływ na otoczenie: Czyszczenie laserowe może generować pewne ilości pyłu, dymu lub oparów, które mogą być szkodliwe dla środowiska. Konieczne jest odpowiednie odprowadzanie tych substancji, aby uniknąć zanieczyszczenia powietrza.

5. Konserwacja i utrzymanie: Urządzenia do czyszczenia laserowego wymagają regularnej konserwacji i utrzymania, aby zapewnić ich prawidłowe działanie. To może wiązać się z dodatkowymi kosztami i wysiłkiem.

Słowa kluczowe: technologia czyszczenia laserowego, wyzwania, ograniczenia, materiały, bezpieczeństwo, koszty, zanieczyszczenia, efekty uboczne, rozmiar, kształt, czas trwania, zasięg, otoczenie, konserwacja, utrzymanie.

Frazy kluczowe: technologia czyszczenia laserowego w przemyśle samochodowym, czyszczenie laserowe w przemyśle lotniczym, czyszczenie laserowe w przemyśle spożywczym, czyszczenie laserowe w przemyśle medycznym, czyszczenie laserowe w przemyśle elektronicznym, czyszczenie laserowe w przemyśle metalowym, czyszczenie laserowe w przemyśle drzewnym, czyszczenie laserowe w przemyśle tekstylnym, czyszczenie laserowe w przemyśle szklarskim, czyszczenie laserowe w przemyśle ceramicznym.

Laser cleaning for removing oil and grease from automotive machinery

Laser cleaning offers numerous advantages over traditional cleaning methods. Firstly, it is a non-contact and non-abrasive technique, which means that it does not cause any damage to the surface of the machinery. This is particularly important for delicate automotive components that require gentle cleaning. Secondly, laser cleaning is a highly precise method that can target specific areas without affecting the surrounding surfaces. This level of precision ensures that only the oil and grease are removed, leaving the machinery intact. Additionally, laser cleaning is a dry process, eliminating the need for water or chemical solvents. This not only reduces the risk of corrosion but also makes it an environmentally friendly cleaning method. Lastly, laser cleaning is a fast and efficient process, significantly reducing downtime and increasing productivity in the automotive industry.

Applications of Laser Cleaning in the Automotive Industry:

Laser cleaning has found widespread applications in the automotive industry for removing oil and grease from various machinery components. One of the primary applications is in engine cleaning. Engines are prone to oil and grease buildup, which can affect their performance and efficiency. Laser cleaning can effectively remove these contaminants from engine parts such as cylinder heads, pistons, and valves, ensuring optimal functioning. Another important application is in brake cleaning. Brake systems are critical for vehicle safety, and any oil or grease residue can compromise their performance. Laser cleaning can efficiently remove these contaminants from brake pads, calipers, and rotors, ensuring reliable braking performance. Additionally, laser cleaning is also used for cleaning transmission systems, fuel injectors, and other automotive components that are susceptible to oil and grease buildup.

Future Prospects:

The future prospects of laser cleaning in the automotive industry are promising. As technology continues to advance, laser cleaning systems are becoming more compact, affordable, and user-friendly. This will enable smaller automotive workshops and garages to adopt laser cleaning as a routine maintenance practice. Furthermore, ongoing research and development in laser technology are focused on enhancing the cleaning efficiency and expanding the range of materials that can be effectively cleaned. This will open up new possibilities for laser cleaning in the automotive industry, including the removal of other contaminants such as rust, paint, and adhesives. With its numerous benefits and growing applications, laser cleaning is poised to revolutionize the way oil and grease are removed from automotive machinery.

Keywords: laser cleaning, oil and grease removal, automotive machinery, traditional cleaning methods, non-contact, non-abrasive, precise, dry process, environmentally friendly, fast and efficient, engine cleaning, brake cleaning, transmission systems, future prospects, compact, affordable, user-friendly, research and development, rust removal, paint removal, adhesive removal.

Long-tail phrases: , benefits of laser cleaning in the automotive industry, applications of laser cleaning in automotive machinery, future prospects of laser cleaning in the automotive industry.

Laser cleaning for removing oil and grease from food processing machinery

One of the key advantages of laser cleaning is its precision. The laser beam can be focused on specific areas, ensuring that only the oil and grease are targeted, leaving the rest of the machinery untouched. This level of precision reduces the risk of damage to delicate components and extends the lifespan of the equipment. Additionally, laser cleaning eliminates the need for harsh chemicals, reducing the environmental impact and ensuring compliance with strict regulations regarding the use and disposal of cleaning agents.

Another benefit of laser cleaning is its efficiency. Traditional cleaning methods often require disassembling the machinery for thorough cleaning, resulting in downtime and loss of productivity. Laser cleaning, on the other hand, can be performed in situ, without the need for dismantling the equipment. This significantly reduces downtime and allows for continuous operation, minimizing disruptions to the production process.

Furthermore, laser cleaning is a safe method for removing oil and grease from food processing machinery. Unlike chemical cleaning, which may leave behind residues that can contaminate the food, laser cleaning leaves no trace of cleaning agents. This ensures that the machinery remains free from any potential contaminants, maintaining the highest standards of food safety and quality.

In terms of cost-effectiveness, laser cleaning proves to be a viable option in the long run. While the initial investment in laser cleaning equipment may be higher compared to traditional cleaning methods, the savings in labor, downtime, and cleaning agents make it a cost-effective solution. Moreover, laser cleaning is a non-abrasive process, which means that it does not cause wear and tear on the machinery. This reduces the need for frequent repairs and replacements, resulting in significant cost savings over time.

In conclusion, laser cleaning offers numerous advantages for removing oil and grease from food processing machinery. Its precision, efficiency, safety, and cost-effectiveness make it an attractive alternative to traditional cleaning methods. By utilizing laser cleaning technology, food processing plants can ensure the cleanliness and hygiene of their machinery, enhance productivity, and maintain the highest standards of food safety.

Keywords: laser cleaning, oil and grease removal, food processing machinery, precision, efficiency, safety, cost-effectiveness, non-abrasive, environmental-friendly, contaminants.

Long-tail phrases:

– : a game-changer in the industry.

– The benefits of laser cleaning in the food processing sector.

– How laser cleaning technology revolutionizes oil and grease removal from machinery.

– Enhancing cleanliness and hygiene in food processing plants with laser cleaning.

– The future of cleaning: laser technology for oil and grease removal in the food industry.

Laser cleaning for removing oil and grease from power generation machinery

Laser cleaning offers several advantages over traditional cleaning methods. Firstly, it is a non-contact and non-abrasive technique, which means that it does not cause any damage to the surface of the machinery. This is particularly important for delicate components that are susceptible to wear and tear. Secondly, laser cleaning is a highly precise method that can selectively remove oil and grease without affecting the underlying material. This ensures that the machinery remains in optimal condition and extends its lifespan. Additionally, laser cleaning is an environmentally friendly process as it does not involve the use of chemicals or generate hazardous waste.

Applications of Laser Cleaning in Power Generation:

Laser cleaning has found numerous applications in the power generation industry. One of the primary areas where it is utilized is in the cleaning of gas turbines. Gas turbines are prone to oil and grease contamination, which can lead to reduced efficiency and increased fuel consumption. Laser cleaning effectively removes these contaminants, restoring the turbine’s performance and reducing maintenance costs. Another application of laser cleaning is in the cleaning of heat exchangers. Heat exchangers are critical components in power plants, and any fouling due to oil and grease can significantly impact their heat transfer efficiency. Laser cleaning ensures the removal of these contaminants, improving the overall efficiency of the power generation process.

Future Prospects:

The future prospects of laser cleaning in the power generation industry are promising. As technology continues to advance, laser cleaning systems are becoming more efficient, compact, and cost-effective. This opens up opportunities for their widespread adoption in power plants and other energy generation facilities. Furthermore, ongoing research and development efforts are focused on enhancing the capabilities of laser cleaning systems, such as increasing their power output and developing specialized laser beams for specific cleaning applications. These advancements will further improve the effectiveness and efficiency of laser cleaning, making it an indispensable tool in the maintenance and operation of power generation machinery.

Keywords: laser cleaning, oil and grease removal, power generation machinery, gas turbines, heat exchangers, efficiency, maintenance costs, non-contact, non-abrasive, environmentally friendly.

Long-tail phrases:

1. : a game-changer in maintenance.

2. The advantages of laser cleaning in power generation: precision, non-abrasive, and environmentally friendly.

3. Applications of laser cleaning in gas turbines: restoring performance and reducing maintenance costs.

4. Laser cleaning in heat exchangers: improving heat transfer efficiency in power plants.

5. The future of laser cleaning in power generation: advancements and widespread adoption.

Laser cleaning for removing oil and grease from chemical processing machinery

Laser cleaning offers several advantages over traditional cleaning methods. Firstly, it is a non-contact and non-abrasive technique, which means that it does not cause any damage to the surface of the machinery. This is particularly important in the chemical processing industry, where delicate components and materials are often involved. Secondly, laser cleaning is a highly precise method that can selectively remove oil and grease without affecting the underlying surface. This level of precision ensures that only the contaminants are removed, leaving the machinery intact and ready for operation. Additionally, laser cleaning is a dry process, eliminating the need for water or chemicals, which can be costly and environmentally harmful. Lastly, laser cleaning is a fast and efficient method, reducing downtime and increasing productivity in chemical processing plants.

Applications of Laser Cleaning in Chemical Processing:

Laser cleaning has found numerous applications in the chemical processing industry. One of the primary uses is in the cleaning of heat exchangers. Heat exchangers are vital components in chemical processing plants, responsible for transferring heat between fluids. Over time, these heat exchangers can become fouled with oil and grease, reducing their efficiency. Laser cleaning offers a precise and effective solution for removing these contaminants, restoring the heat exchangers’ performance. Another application of laser cleaning is in the cleaning of pipelines and tanks. Oil and grease buildup in pipelines and tanks can lead to clogs and blockages, disrupting the flow of chemicals. Laser cleaning can efficiently remove these contaminants, ensuring the smooth operation of the chemical processing system. Additionally, laser cleaning can be used for the maintenance and cleaning of various machinery components, such as pumps, valves, and reactors, prolonging their lifespan and optimizing their performance.

Future Prospects:

The future prospects of laser cleaning in the chemical processing industry are promising. As technology continues to advance, laser cleaning systems are becoming more efficient, compact, and cost-effective. This opens up opportunities for smaller chemical processing plants to adopt laser cleaning as a viable cleaning solution. Furthermore, ongoing research and development efforts are focused on enhancing the capabilities of laser cleaning systems, such as increasing their power and improving their adaptability to different surfaces and contaminants. These advancements will further improve the efficiency and effectiveness of laser cleaning in removing oil and grease from chemical processing machinery.

Keywords: laser cleaning, oil and grease removal, chemical processing machinery, benefits, applications, future prospects.

Long-tail phrases:

1. Laser cleaning for removing oil and grease from chemical processing equipment.

2. Benefits of laser cleaning in the chemical processing industry.

3. Applications of laser cleaning in heat exchanger maintenance.

4. Laser cleaning for pipeline and tank cleaning in chemical processing plants.

5. Future prospects of laser cleaning technology in the chemical processing industry.

Laser cleaning for removing oil and grease from packaging machinery

One of the key advantages of laser cleaning is its ability to target specific areas without affecting the surrounding components. This precision allows for thorough cleaning of intricate machinery parts, ensuring optimal performance and reducing the risk of breakdowns or malfunctions. Additionally, laser cleaning eliminates the need for harsh chemicals or solvents, making it a safer and more environmentally friendly option.

Another benefit of laser cleaning is its efficiency and speed. Traditional cleaning methods often require disassembling the machinery for thorough cleaning, resulting in significant downtime and production losses. Laser cleaning, on the other hand, can be performed in situ, without the need for dismantling or interrupting the production process. This saves time, reduces costs, and increases overall productivity.

Furthermore, laser cleaning is a versatile technology that can be used on various types of packaging machinery, regardless of their size or complexity. It can effectively remove oil and grease from conveyor belts, rollers, gears, nozzles, and other components, ensuring optimal performance and extending the lifespan of the machinery. Laser cleaning can also be used for routine maintenance, preventing the buildup of contaminants and reducing the frequency of major cleaning operations.

In conclusion, laser cleaning has revolutionized the process of removing oil and grease from packaging machinery. Its precision, efficiency, and environmental friendliness make it an ideal choice for industries that prioritize cleanliness and productivity. By utilizing laser cleaning technology, manufacturers can ensure the highest quality of their products, minimize downtime, and reduce maintenance costs.

Keywords: laser cleaning, oil and grease removal, packaging machinery, cleanliness, contamination, precision, efficiency, environmental friendly, non-contact, non-abrasive, laser beams, vaporize, sublimate, microscopic crevices, specific areas, performance, breakdowns, malfunctions, harsh chemicals, solvents, speed, downtime, production losses, in situ, versatility, conveyor belts, rollers, gears, nozzles, routine maintenance, buildup, manufacturers, quality, productivity.

Long-tail phrases: , non-contact and non-abrasive oil and grease removal, precision cleaning of packaging machinery, environmentally friendly oil and grease removal, efficient and fast cleaning method for packaging machinery.

- Laser cleaning for removing contaminants from solar panels - 22 April 2024

- Laser cleaning for removing oil and grease from machinery - 28 January 2024

- Jak skutecznie zarządzać dokumentacją związaną z wynajmem mieszkania w Warszawie? - 24 October 2023